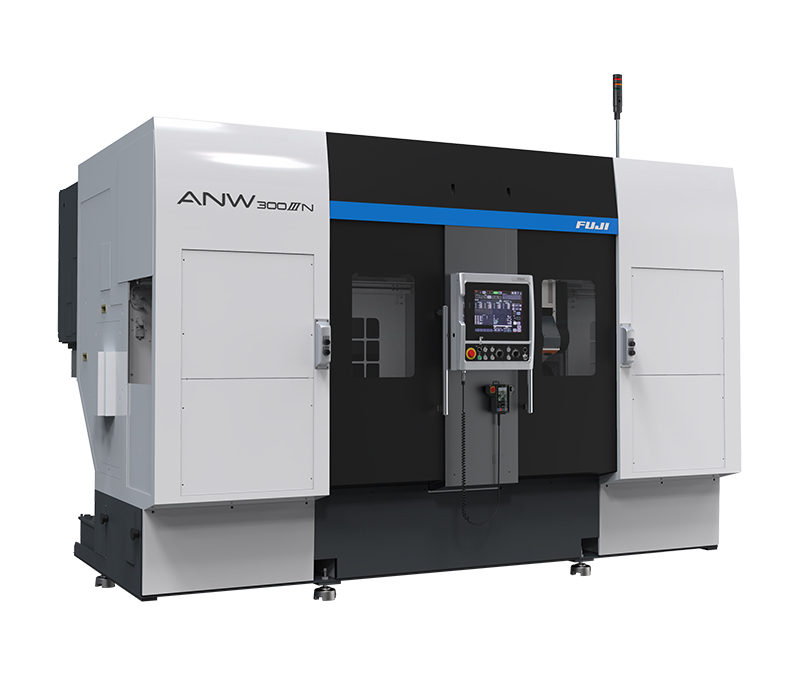

ANW-300III

ANW-300III Twin Spindle Lathe

Flexible Machining Operations on one machine with built in Fuji Robot Automation. Fully Automated Machine with High Accuracy for Front and Back Machining or Multiple Machining Operations. Further evolution of Fuji's original multi-functional cell with improved efficiency and working environment.

- Built-in 4-axis swing-arm robot with FANUC Control

- Selectable Turrets according to the type of machining

- Increase productivity by performing interrupted and finish cuts simultaneously

- Advanced Operability

- Vertical bed for effective chip disposal

- Auxiliary loader for faster load/unload

- Optional dual tailstock

-

Recommended Work Size Dia. - mm (inch) 250 x 100 (9.8 x 3.9) Spindle Diameter - mm (inch) 100 (3.9) Spindle Nose A2-6 Spindle Bore Dia. - mm (inch) 56 (2.2) Spindle Speed - rpm Max. 3500 Spindle Motor - kW (hp) 15/18 (20/25) No. of Tool Stations 8 (12) Turret Index Time - sec. 0.4 Turret Mechanism 8 Stations Cam

12 Stations 2-Piece Coupling

12 Stations Live Tool CamChuck Size - inch 8 - 10 CNC Control FANUC Slide Stroke: X-axis - mm (inch) 270 (10.6) Slide Stroke: Z-axis - mm (inch) 455 (17.9)

385 (15.2) Live ToolsServo Motor: X-axis - kW (hp) 4 (5.4) Servo Motor: Z-axis - kW (hp) 4 (5.4) ROBOT SPECIFICATIONS: Robot 292L III Carrying Capacity - kg (lbs) 7 + 7 (15 + 15) Robot Controller FANUC -

Work Length 315mm (12.4 in) Tailstock (Optional) MT.4 live center -

- Specifications are subject to change without notice.

- Larger capacity also available. Consult Fuji on your application.